Solid Oxide Fuel Cells

Overview

P250i Solid Oxide Fuel Cells (SOFC) provide a reliable source of DC power by converting chemical energy into electricity. Powered by propane or natural gas, the P250i is capable of providing days, weeks and even months of reliable, clean, extended-run backup power protection for a variety of critical infrastructure needs. The P250i is manufactured by Edge Autonomy (formerly Adaptive Energy, LLC).

1500+ Solid Oxide Fuel Cells Installed

How Solid Oxide Fuel Cells Works

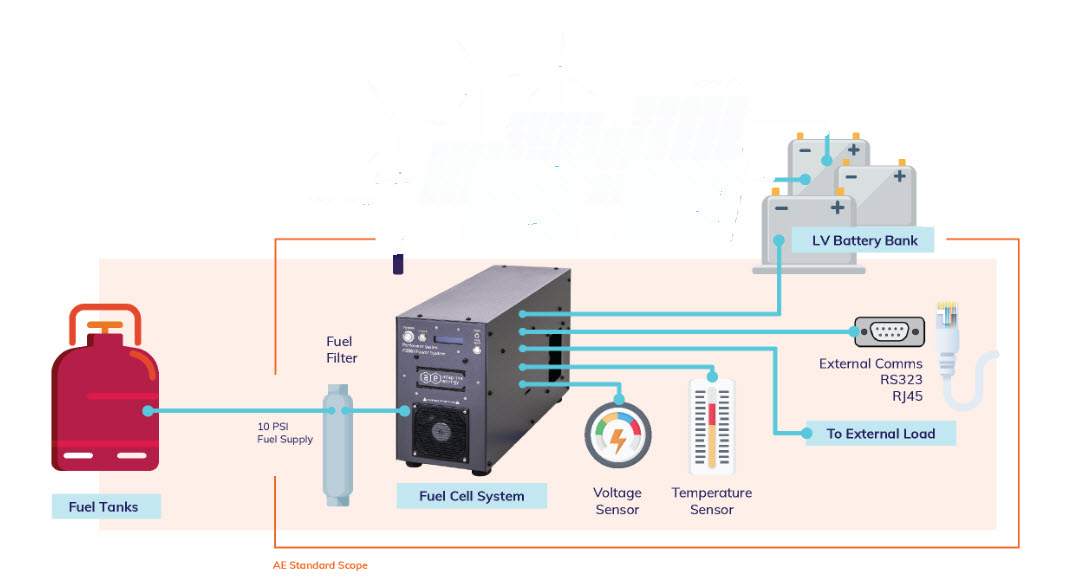

The P250i Solid Oxide Fuel Cells (SOFC) are designed to work with new or existing power infrastructure including the utility grid, batteries, solar charge controllers, dc-dc converters, etc. Powered by readily available and low cost propane or natural gas, the P250i has the ability to sit in standby mode for months to years at a time monitoring battery voltage. The P250i will automatically start once the batteries dip below a pre-determined lower threshold voltage. After a 25-30 minute startup period, the P250i will begin charging the batteries and powering the load. Once the batteries reach a pre-determined upper threshold voltage, the P250i will automatically begin to cool-down and return to standby mode.

P250i vs. Diesel/Gas Generators

While diesel/gas generators have been widely used for backup power generation due to their high power and low initial cost, their ongoing maintenance needs and associated costs can often be overlooked. It is essential to change the oil every few hundred hours and rebuild the engine or replace/scrap it entirely after just a few years. Furthermore, diesel/gas generators are noisy, have dirty emissions, and are prone to theft. Fortunately, solid oxide fuel cells are gaining popularity as a cleaner, quieter, and more efficient backup power solution. These cells use a non-polluting electrochemical process to generate electricity, emitting only water and waste heat as byproducts. They also require significantly less maintenance, making them a more cost-effective and sustainable option for critical applications.

.

P250I SOLID OXIDE FUEL CELLS ADVANTAGES

Propane or Natural Gas

The P250i solid oxide fuel cells are powered by readily available and low cost propane or natural gas. During operation the P250i efficiently burns 1/4lb LP/hour and can provide 130-160 hours of run-time on two (2) BBQ style propane tanks.

Zero Maintenance

The P250i needs no oil changes, has no moving parts and requires no routine maintenance. In fact, the P250i can sit in standby mode for months to years at a time monitoring battery voltage and only run when its called upon.

All-Climate Performance

The P250i utilizes a ceramic electrolyte which is not susceptible to freezing and thawing cycles common among other fuel cell types. Its robust design allows the P250i to reliably operate in virtually any climate -40°F to 122°F.

Easy Integration

The P250i integrates seamlessly with the utility grid, generators, batteries, solar & wind, solar charge controllers, DC-DC converters, fused external communications, computers, modems and other customer electronics.

Telematics Monitoring

Telematics (optional pkg) provides real-time, historical operational visibility via cellular/satellite service to web portal dashboard with data logging, status reports, 2-way communications and more to reduce site trips and increase system uptime.

Proven Deployment

Check out a handful of installations in our Photo Gallery.

P250i Technical Specs

- Charging Power: 250 Watts

- Operating Voltage: 12VDC, 24VDC, 48VDC

- Charging Amps: 20A, 10A, 5A

- Fuel Consumption (LPG): 0.25lbs/hour

- Fuel Consumption (CNG): 3.27m³/day

- Standby Power Draw: <0.05W

- Design Target Life: 250 Cycles / 3,000 Hours

- Operating Temperature: -40°F to 158°F

P250i Applications

When faced with prolonged power disruptions due to natural disasters or inadequate charging systems, the P250i with solid oxide fuel cells steps in, ensuring dependable and efficient supplemental power. It’s a lifeline for charging batteries and sustaining vital operations amidst chaos.

Railroads

-Highway Crossings

-Intermediate Signals

-Control Points

-Solar Hybrids

-Telecom Equipment

-Disaster Prepardness

-Security/Surveillance

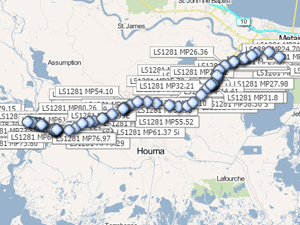

Oil & Gas

-SCADA Equipment

-Remote Telemetry

-Measurement Systems

-Monitoring

-Solar Hybrids

-Field Automation/Instrumentation

-Security/Surveillance

Critical Infrastructure

-Traffic Intersection Signaling

-Highway Call Boxes

-Advanced Warning Systems

-Border Security/Surveillance

-Network Infrastructure

-Weather Stations

-Emergency Management Systems

We’re pleased to announce that our P250i Solid Oxide Fuel Cell was selected as a C&S products category winner of Progressive Railroading’s 4th annual Reader’s Choice Awards program!

Powered by propane, our P250i Solid Oxide Fuel Cell automatically senses low battery voltage to turn on and charge battery banks at grade crossings, signals and other wayside assets during extended power outages.

The 2023 Progressive Railroading Reader’s Choice Awards program recognizes products that best meet the industry’s needs as selected by subscribers of Progressive Railroading magazine.

Located in Ann Arbor, Michigan, Edge Autonomy (formerly Adaptive Energy, LLC) designs and manufactures the P250i Solid Oxide Fuel Cell (SOFC) for back up and portable power applications. Adaptive Energy’s tubular ceramic cell design allows them to offer compact and rugged systems that can operate in the most austere and remote locations. The company offers 250-500 watt fuel cell systems that are powered by globally available and energy dense propane, butane and natural gas.

Case Studies

Just a few examples of the hundreds of SOFC systems we’ve supplied for critical applications since 2014.