PowerGen Stirling Engines

Overview

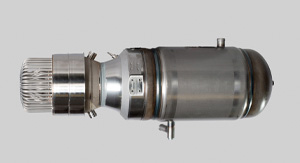

Qnergy’s PowerGen Remote Power Generators combine high efficiency Free Piston Stirling Engine (FPSE) technology with advanced combustion capabilities to efficiently transform propane, well gas and natural gas into electricity. The external combustion engine and automatic control system enable the generator to produce steady, dependable power from 1.8kW to 5.6kW at 120/240 VAC (with additional voltage configurations available). PowerGen Stirling Engines are manufactured by Qnergy.

*Please Note*

RedHawk Energy is a distributor for Qnergy in the rail transportation market in the US & Canada. We do not supply or market the PowerGen to residential customers and oil & gas customers. In fairness to other distributors we will not engage or respond to requests for info or pricing for markets outside of the rail transportation market.

– RedHawk Energy Systems, LLC

Free-Piston Stirling Engine Technology

Qnergy’s Free-Piston Stirling Engine (FPSE) generator can transform virtually any heat source into electricity. Once heat is applied to the FPSE the heat exchangers maintain a temperature differential across the engine causing the helium to shuttle back-and-forth inside the engine, expanding and contracting. The oscillating helium drives the linear reciprocating motion of the piston, which by means of an integral linear alternator, directly converts the reciprocating motion of the piston into electrical power.

The Qnergy engine has fewer moving parts than traditional kinematic Stirling engines, and no direct-contact points that cause wear and require lubrication. The Qnergy engine is truly a maintenance-free technology that offers long-life performance, two key features that make it an ideal power source.

PowerGen Features & Benefits

PowerGen Stirling Engines have several advantages over conventional diesel/gas generators.

Multiple Fuel Sources

The PowerGen can operate seamlessly with a variety of fuel supplies including: propane, natural gas, ethane, bio-gas, as well as multiple associated gas streams of differing caloric values.

Minimal Maintenance

The PowerGen has fewer moving parts than traditional kinematic Stirling Engines and no direct contact points that cause wear and require lubrication. A yearly 1-hour inspection is recommended.

Low Emissions

Compared to Gas/Diesel Generators that require special permitting and emit harmful pollutants, the PowerGen has low emissions and requires no special permitting.

Simple Integration

By means of its flexible and modular design, the PowerGen can be tailored to provide a broad range of power output (1.8kW,5.6kW) and output voltages (120/240 VAC, 24/48VDC) to meet the electrical requirements of each specific site load.

Load Following Capability

The PowerGen features a load following controller that monitors live load conditions and matches fuel consumption to those live conditions, saving fuel and costs.

Design Life

Free piston Stirling Engine technology was pioneered in space. Unlike other technologies there is no reliability reduction for multiple start-stops or continuous operation. Design life for commercial applications is conservatively estimated at 80,000 hours with zero maintenance!

PowerGen Technical Specs

- Output Power: 1.8kW (PowerGen 1800 Series)

- Output Power: 5.6kW (PowerGen 5650 Series)

- Nominal Operating Voltage: 120/240 VAC (other configurations available)

- Operating Temperature: -13°F to 122°F

(Cold Temperature pkg available down to -40°F) - Weight: 866 lbs

- Dimensions: 69.4″L x 28.1″W x 57.2″H

- Recommended Pad Dimensions: 72″L x 36″W

- Recommended Pad Base: Level Gravel, Concrete, Rail Ties

- Fuel Pressure Range (Propane): 2-10 PSI

- Fuel Pressure Range (Natural Gas): 3-50 PSI

- Cabinet Electrical Rating: IP54

- Certification: cETLus (UL2200), (CSA C22.2#100/C22.2#14)e3w

- Generator Design Life: 80,000+ Hours (No start/stop limitations)

*Specifications subject to change

PowerGen Rail Applications

The PowerGen Stirling Engines are a great fit for remote wayside rail signaling and telecommunications applications (control points, interlockings, remote sites, telecom stations, etc.), due to their rugged and robust construction, extremely long life and minimal maintenance needs.

Prime Power (Off-Grid)

The PowerGen can be used as a prime power generator for remote locations where utility power connection is unavailable and/or too costly. The PowerGen is capable of cycle charging or running continuously for 80,000+ hours with no start/stop limitations.

Backup Power

The PowerGen can be used as a backup power system for locations with AC utility power connection. A transfer switch can signal the PowerGen to start and provide power during an AC power outage. Unlike some power technologies, the PowerGen has no start/stop cycle limitations.

Solar Hybrids

The PowerGen is well suited to provide supplemental power to new or existing Solar Power Systems. During periods of insufficient solar production (ex: winter months), the PowerGen is signaled to start and provide power to charge batteries. This setup also conserves fuel during summer.

Qnergy Provides Energy

Qnergy is a company focused on providing energy to a world market looking for innovative, cost-effective and efficient ways to energize the future. With more than 40 years of expertise and proven reliability, Qnergy brings proprietary, high-performance Stirling engine technology to the marketplace for commercial and industrial applications. Qnergy’s PowerGen Stirling Engines are proudly Made in the USA!

RedHawk Energy is a distributor for Qnergy in the rail transportation market in the US & Canada. RedHawk Energy does not quote, supply or market the PowerGen to residential customers and oil & gas customers. In fairness to other distributors we will not engage or respond to requests outside of our coverage.